Grasping DTF Printing: Advice for Achieving Vibrant and Sturdy Prints

In the globe of fabric printing, accomplishing resilient and dynamic prints is a desired ability that can boost the top quality of your outcome. From picking the appropriate products to fine-tuning print settings and perfecting post-printing finishing techniques, there are various factors that can influence the outcome of your prints.

DTF Printing Basics

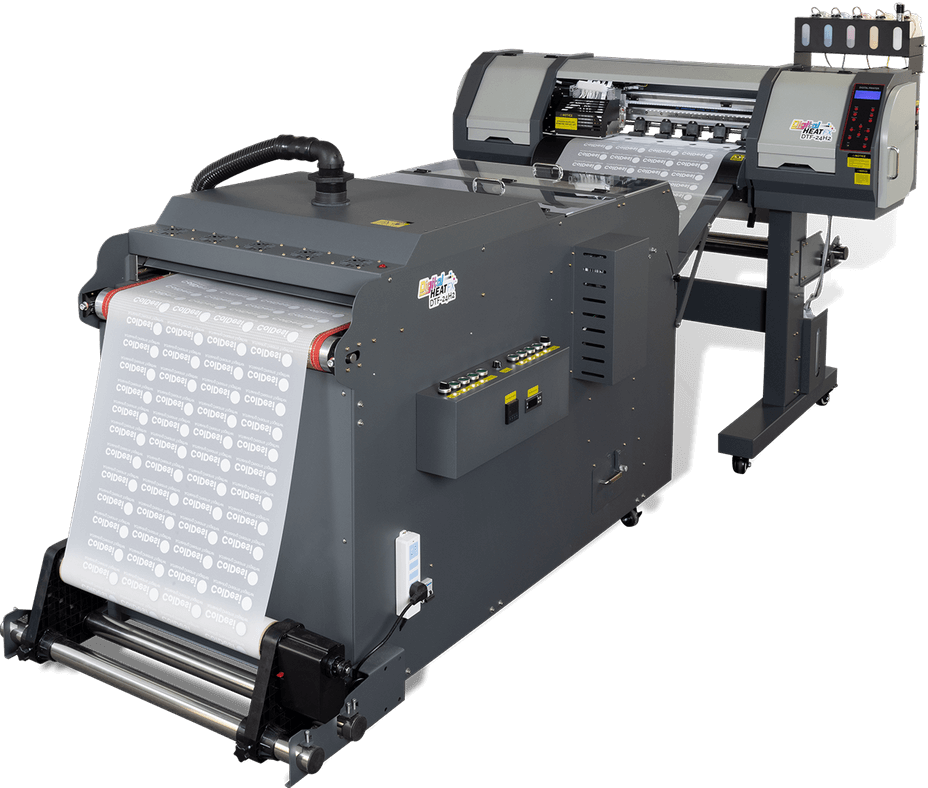

For those new to the globe of fabric printing, comprehending the basics of DTF printing is necessary to grasping this innovative technique. Straight to Movie (DTF) printing is a modern-day approach that entails transferring designs from an unique movie onto different textiles making use of a heat press. Unlike typical techniques like screen printing, DTF offers benefits such as dynamic colors, detailed describing, and the capacity to print on diverse products like cotton, polyester, and blends.

The process starts by printing the design on an unique DTF movie utilizing a compatible printer with CMYK or CMYKW ink collections. When the layout is published, it is then healed with a heat press to develop a long lasting and lasting print. DTF printing is known for its capacity to recreate intricate styles with high accuracy and color precision, making it a popular selection for companies looking to produce custom clothing, advertising products, and more.

Selecting the Right Products

The sticky powder acts as a bonding agent in between the published style and the fabric, so it has to have solid bond homes to ensure a durable and long-lasting transfer. By thoroughly picking the ideal materials for DTF printing, printers can boost the quality, vibrancy, and long life of their prints.

Maximizing Print Setups

When intending to achieve the finest outcomes in DTF printing, meticulous interest to enhancing print setups is essential for ensuring top quality and exact transfers onto fabrics. One vital aspect to consider when enhancing print setups is the resolution.

An additional important setting to enhance is the print speed. Discovering the ideal equilibrium in between rate and high quality is crucial. While increasing the speed can improve efficiency, it may compromise the final print's clarity and color saturation. Explore different speeds and observing the results can help determine the ideal setup for every print task - DTF Printing.

Moreover, tweak color profiles find more information and ensuring proper color monitoring are vital for accomplishing constant and exact shades across various prints. By adjusting color setups and profiles, printers can reduce color deviations and generate uniform results, boosting the general print quality and consumer contentment.

Preparing Art Work for DTF Printing

To make sure optimal outcomes in DTF printing, careful attention to information is necessary when preparing artwork for transfer onto fabrics. Begin by choosing high-resolution photos to preserve clarity and intensity in the final print. Vector graphics are liked as they can be easily scaled without shedding high quality. Transform the artwork to CMYK color mode to make sure that the colors convert accurately from display to check these guys out print. Adjust the shade levels and comparison as required to enhance the vibrancy of the layout. When adding message to the artwork, select fonts that are readable and suitable for the designated dimension. Keep in mind to mirror the last design prior to publishing to guarantee that it moves correctly onto the garment. Furthermore, take into consideration the fabric kind and shade when selecting the art work, as these variables can affect the final look. By following these actions and paying very close attention to the information, you can prepare artwork that is optimized for long lasting and vivid DTF prints.

Post-Printing Finishing Strategies

Applying reliable post-printing ending up strategies is vital to improving the toughness and visual appeal of DTF prints on fabrics. When the printing procedure is total, applying heat to the published style is vital.

When the movie is eliminated, the print might call for extra healing time to additionally set the ink into the textile. This step aids enhance the washability and longevity of the print, ensuring it can stand up to multiple laundry cycles without fading or cracking.

Furthermore, cutting any excess movie around the layout can provide the last print a expert and tidy look. Putting in the time to correctly complete DTF prints post-printing can significantly affect the total quality and longevity of the textile layout.

Final Thought

In verdict, mastering DTF printing needs a detailed understanding of the basics, selecting suitable materials, maximizing print settings, preparing artwork successfully, and making use of post-printing finishing techniques. By complying with these tricks and suggestions, one can accomplish vivid and sturdy prints that satisfy their preferred high quality requirements. Regular technique and focus to information are important in achieving successful outcomes in DTF printing.

From selecting the best materials to tweak print settings and developing post-printing finishing strategies, there are various variables that can influence the outcome of your prints. Unlike typical approaches like display printing, DTF uses benefits such as lively shades, elaborate outlining, and the ability Visit Website to print on varied products like cotton, polyester, and blends.

When the style is printed, it is then cured with a warmth press to develop a sturdy and resilient print.When aiming to attain the finest results in DTF printing, careful interest to optimizing print setups is essential for making sure exact and premium transfers onto fabrics.In verdict, grasping DTF printing requires a comprehensive understanding of the basics, choosing ideal materials, optimizing print setups, preparing artwork efficiently, and utilizing post-printing ending up methods.

Comments on “DTF Printing Demystified: Everything You Need to Learn About Direct-to-Film”